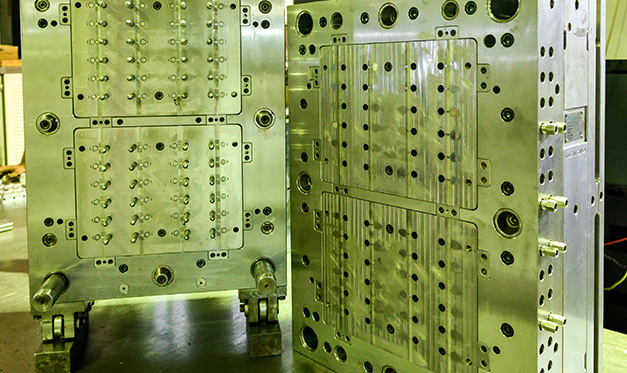

High Tech Tooling solutions

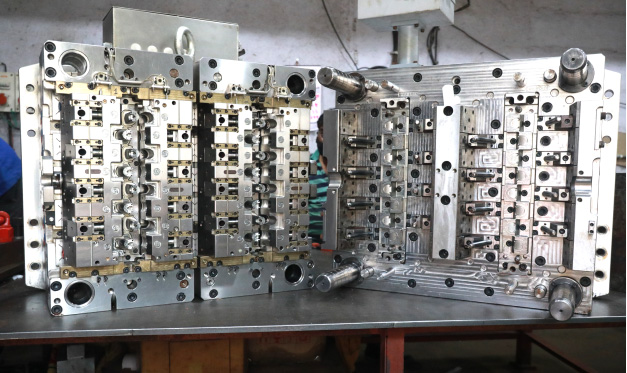

Mould Making

Being in the industry for over 30 years Jay Precision possesses the technical expertise and knowhow to produce sophisticated tooling for a variety of industrial sectors including pharmaceutical, irrigation, consumer goods and many others. Our end-to-end development and collaborative approach ensures exceptional mould making solutions tailored to your needs. Our team of over 15 design engineers have extensive experence in product modelling for a range of functional devices in various sectors. Facilitated by the latest CAD/CAM/CAE systems, we provide cost effective tooling solutions for all engineering thermoplastics, moulds for liquid silicone, high precision multi-cavity moulds, 2K, coining technologies and die cast parts. Turn around times range anywhere between 5-10 weeks dpending on the complexity of the tool.

Our state of the art toolroom is equipped with over 50CNC’s from world renowned machine tool manufacturers such as Hermle, Charmilles, Makino, Tornos, Haas etc. These include 5-axis simultaneous machining centres , turn mills, EDM’s and so on. We work with cutters as small as 0.2mm, spindle speeds of upto 150K rpm and machine hard parts up to 55HRc. This enables us to produce complex geometries and maintain the level of precision necessary for producing an accurate part. Our metrology systems include CMM’s and vision inspection systems from Keyence and Rapid I.

Our Capabilities

Integrated Innovation for Excellence

High precision

Delivering exceptional accuracy for every project.

Quick Lead Times

Depending on complexity this can range anywhere between 5-12 weeks

Short Cycle times

Cycle times as low as 6 seconds.

Complex Design Solutions

Expertly navigating intricate design challenges.

High Capacity

Upto 600 moulds per year

Superior Quality

Ensuring high precision outcomes with unwavering attention to detail.

Projects

Micro Centrifuge Tube 2ml

Material : PP

Cavitation : 48 cavity Fully Hot runner Valve Gated (HRS by Mould Masters)

Cycle Time : 7 seconds

LSR Baby Mask

Material : LSR

Cavitation : 4 cavity Fully Hot runner Valve Gated (HRS built inhouse)

Cycle Time : 120 seconds

Outer Dripper

Material : PBT

Cavitation : 32 cavity semi Hot runner (HRS built by Mould Masters)

Ejection : Hydraulic Unscrewing

Cycle Time : 25 seconds

Manufacturing Infrastructure